Case Study: Transform Product Definition for a Global Diagnostics Leader

Background

The company recognized that engineering strength alone wasn’t enough. They engaged TCGen to help ensure the new platform would be a market success, not just a technical one.

The Challenge

The client’s previous platform upgrades often missed the mark with customers. They saw recurring issues:

- Missed sales forecasts and post-launch redesigns

- Products that lagged competitors in perceived value

- Teams making product decisions based on assumptions rather than validated insights

They needed a repeatable process to connect deeply with customer needs—beyond traditional market research—and translate those insights into actionable product requirements.

The TCGen Approach: Market-Driven Product Definition (MDPD)

TCGen applied its Market-Driven Product Definition (MDPD) framework, a methodology detailed in Customer-Centric Product Definition by Sheila Mello (a TCGen Principal). MDPD builds on the principles of design thinking—emphasizing empathy, cross-functional learning, and iterative synthesis—but adapts them for complex B2B and industrial environments, where physical products and long development cycles make prototyping costly.

The process unfolds in five stages, from framing customer segments to deriving prioritized requirements. For this engagement, TCGen guided the client’s flagship project team through each stage, acting as both coach and facilitator rather than a “black-box” consultant.

Step 1: Framing and Team Formation

We began by assembling a cross-functional core team of approximately 20 participants—product managers, engineers, operations, quality, and marketing staff—representing a total program organization of about 150. Rather than delegating customer discovery solely to marketing, TCGen trained and coached this diverse team to participate directly in fieldwork.

This approach is central to MDPD: when engineers and operations staff hear the “voice of the customer” firsthand, they internalize user pain points and constraints more deeply than any report could convey.

Step 2: Customer Visits and Voice of the Customer Research

TCGen and the team built a visitation matrix, segmenting the market into five key customer types across three regions (Americas, Europe, and developing markets). Within each segment, they identified multiple stakeholder roles—purchasing managers, lab technicians, medical staff, and regulatory personnel—who influenced product adoption.

The team conducted roughly 20 customer visits, encompassing over 100 in-person interviews across these segments. Each visit involved a moderator, observer, and note-taker—often with an engineer or quality specialist in the room—to ensure multiple perspectives captured the full context of product use.

Step 3: Synthesis and Affinity Mapping

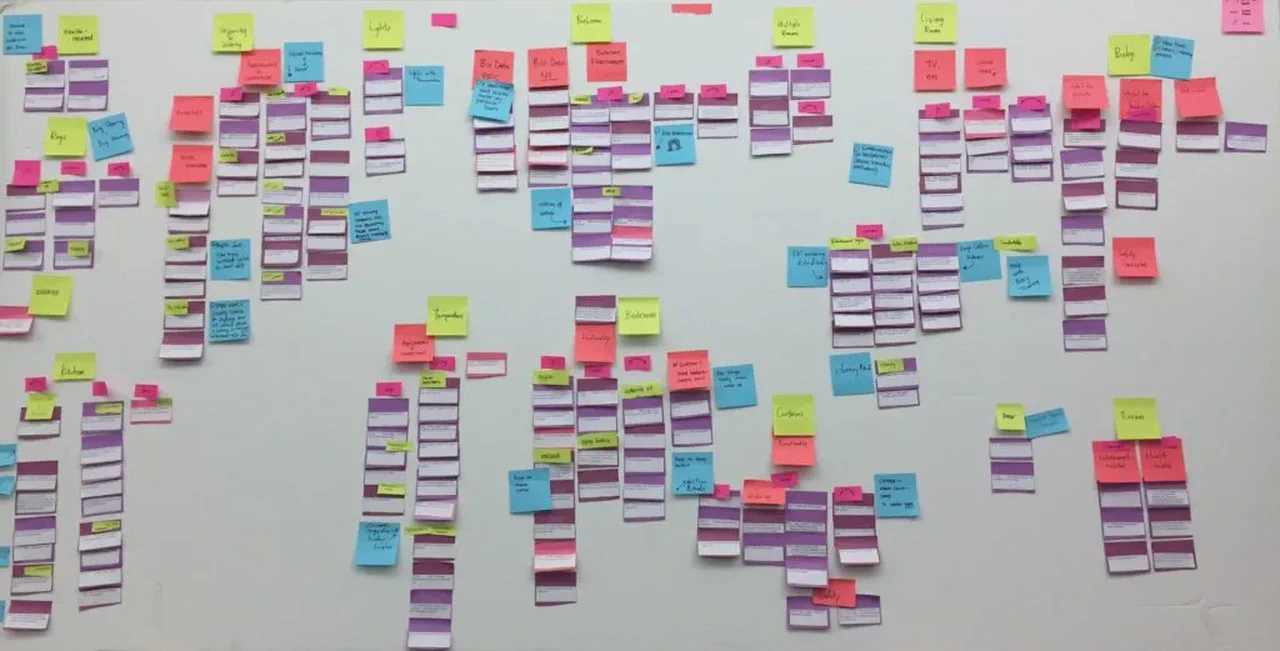

After the interviews, the team synthesized findings using affinity maps—handwritten Post-its covering entire walls—grouping hundreds of observations into emerging themes.

These patterns revealed both unmet needs (features customers wished they had) and basic expectations (features taken for granted but essential for satisfaction). This phase transformed scattered anecdotes into structured insight.

Step 4: Quantitative Validation via the Kano Model

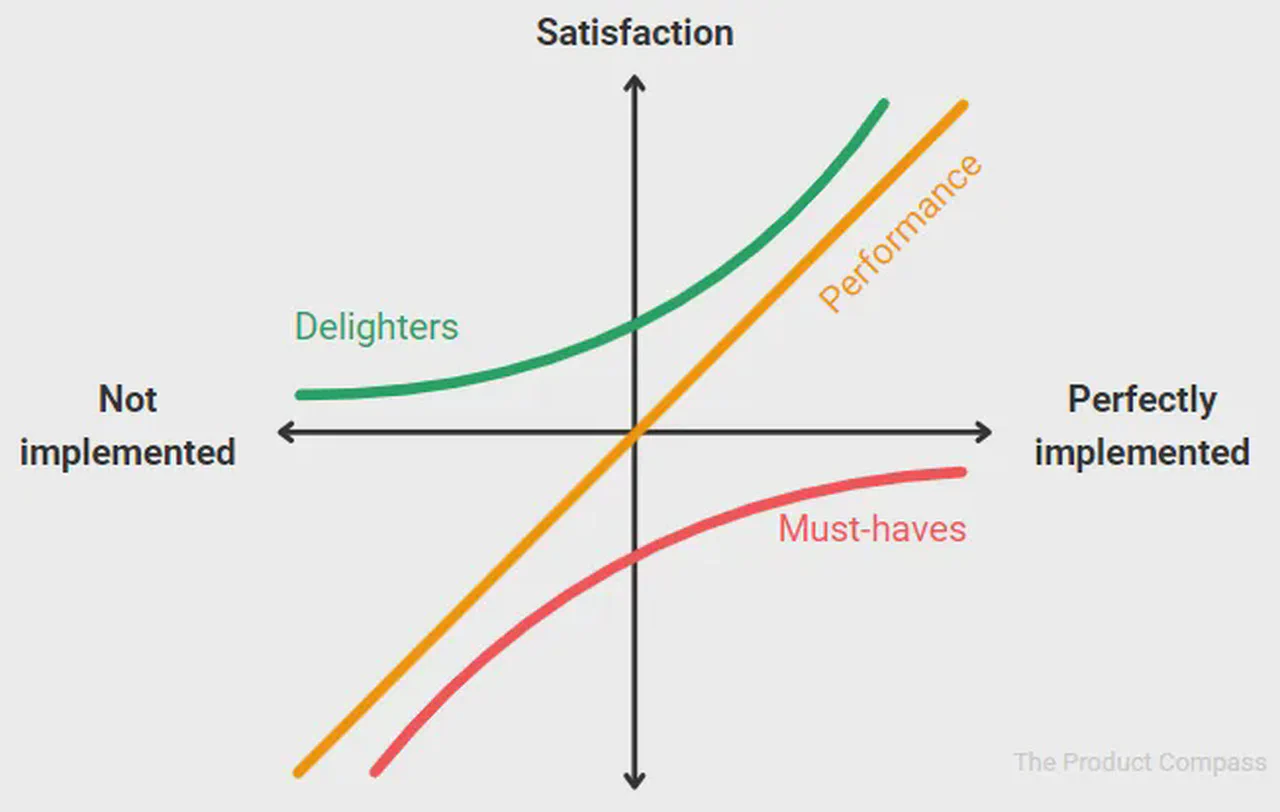

To validate these qualitative insights, TCGen introduced the Kano Model, a quantitative method that classifies requirements into three categories:

- Must-Be: Basic attributes customers expect (e.g., accuracy, reliability).

- One-Dimensional (Performance): Attributes where “more is better” (e.g., faster results, higher throughput).

- Delighters: Unexpected features that create excitement (e.g., intuitive user interface, reduced maintenance).

By surveying representative customers, the team identified which potential features were table stakes, which would differentiate, and which could delight. This balance guided the team’s prioritization and clarified trade-offs between cost, complexity, and customer impact.

Step 5: Translating Insights into Product Requirements

The final stage focused on transforming customer insights into actionable, traceable product requirements. TCGen coached the team through this process but ensured the client authored the final requirements themselves—building internal ownership and capability.

Rather than producing a single “consultant report,” the deliverables were embedded capabilities: a repeatable process, trained facilitators, and a cross-functional mindset for future programs.

Results

The new product launched successfully, replacing the previous generation and becoming the company’s #1 revenue-generating platform for over 17 years.

Key outcomes included:

- Dramatically improved sales and market share due to stronger alignment with customer needs.

- Reduced rework and faster time-to-market, as requirements were validated early.

- Enduring cultural change, with engineers and marketers collaborating effectively in early-stage product definition.

Five years after launch, the program manager called TCGen to share that “the process you taught us was amazing—it made our most important product the number one seller in the company.”